By Kylie Wright

What is CCUS?

The COP26 Summit, the global climate conference attended by over 100 world leaders, takes place this week in Glasgow, Scotland. This will be the most significant climate meeting since the Paris Agreement was signed in 2015, aiming to limit the global temperature increase to well below 2 degrees Celsius and avoid the most severe consequences of climate change. The intervening years have seen a varied commitment to these challenging goals, but some groups have come forward with compelling potential solutions to climate change. An interesting and tangible solution gaining attention is carbon capture, utilization, and storage (CCUS). Surprisingly, the CCUS industry has a lot in common with the produced water management industry.

Fundamentals of CCUS

There are some essential items to know before we describe the nexus of water management and carbon dioxide (CO2) storage. CCUS technologies capture CO2 from fuel combustion and industrial processes using liquid solvents and other separation methods (Figure 1). The captured CO2 is pressurized and chilled to a liquid state and transported via pipeline, truck, and ship. While some captured CO2 may be utilized as a feedstock or unaltered additive to support industrial processes (like Enhanced Oil Recovery [EOR]), services, and products, the vast majority must be stored.

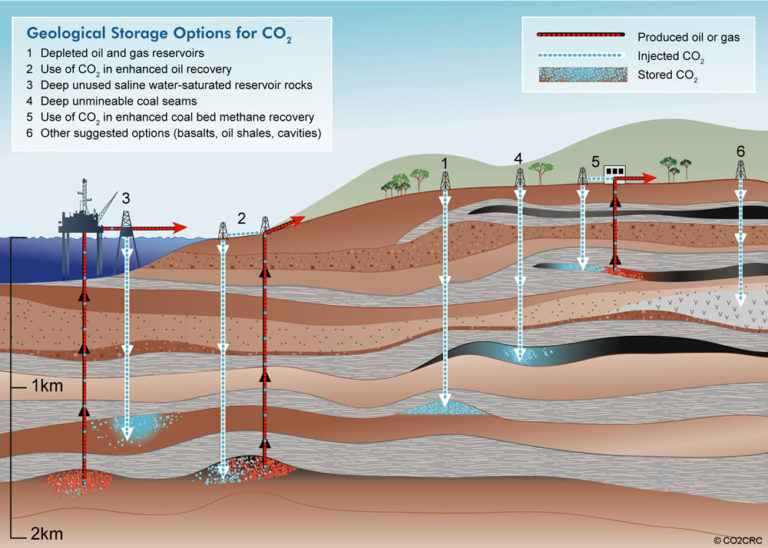

Storage of CO2 primarily implies the disposal of CO2 by injection into the subsurface. CO2 may be stored in depleted oil and gas reservoirs, deep saline aquifers, deep unmineable coal seams, or mafic [1] and ultramafic [2] rock formations (Figure 2). The U.S. Department of Energy estimates that the U.S. has approximately 2,400 billion metric tons of potential subsurface CO2 storage availability [3].

CARBON STORAGE BY THE NUMBERS

THE NEXUS OF WATER AND CARBON

There is the potential for a symbiotic relationship between water and CO2. A large portion of produced water, particularly in the Permian, is disposed of in depleted oil and gas reservoirs, which are also primary targets for CO2 sequestration. CO2 is already regularly used as part of EOR operations; thus, the infrastructure and expertise for managing CO2 exists within the oil and gas industry. Additionally, in many oil and gas producing basins, the research and development needed to characterize the subsurface geology thoroughly, build out necessary infrastructure, and develop an understanding of best management practices for subsurface injection has been completed, and the cost of doing so already realized. Produced water disposal wells (Class I and II) and CO2 injection wells (Class VI) are even regulated under the same broad Underground Injection Control Well Class system [5]. Since water can be used as a disposal medium for CO2, use of Underground Injection Control program Class II wells, which are easier to permit than CO2 injection wells (Class VI), could possibly be used for CO2 storage. Doing so eliminates concerns around injecting pure phase CO2, which is buoyant (prone to subsurface migration) and may react with surrounding minerals or fluids.

Opportunity Abounds

CCUS is emerging as one of the most technologically feasible options of suitable scale to significantly reduce CO2 emissions, and any set of global climate solutions will invariably include CCUS as part of the plan. Currently, there is a lack of economic incentives to support large-scale CCUS development, which increased federal tax incentives could alleviate. While legislators deliberate on that possibility, some CCUS could be supported by the mutually beneficial operation of being disposed alongside produced water. This option would magnify the existing federal tax incentive for CCUS by leveraging disposal economics; suddenly, oilfield water managers could be entitled to a tax benefit if they dispose of both water and carbon.

On the other hand, if increased federal support is provided or the market forces shift, the kind of large-scale CCUS needed would be more efficiently completed by injecting pure liquid phase CO2. Even in that case, the oil and gas and water management industries are well situated to participate by using their existing experience of and assets for the large-scale transportation of pressurized fluid. As we wait to see where the federal government lands on the future of CCUS, the overlap between water and carbon continues to grow across the world, and good stewardship of our natural resources will continue to require thoughtful partnership and accurate data to create insightful solutions.

[1] An igneous rock rich in iron and magnesium.

[2] An igneous rock very rich in iron and magnesium with very little silica content.

[3] Department of Energy. https://www.energy.gov/fecm/articles/does-carbon-utilization-and-storage-atlas-estimates-least-2400.

[4] IEA. 2013. Technology Roadmap Carbon Capture and Storage. https://www.iea.org/reports/technology-roadmap-carbon-capture-and-storage-2013.

[5] EPA UIC Wells. https://www.epa.gov/uic.